Flanges are piping components bolted together using gasket in between two flanges as a sealing material. A flange can also be a plate or ring to form a rim at the end of a pipe when fastened to the pipe. Flanges are used to connect pipes with each other, to valves, to fittings, and to specialty items such as strainers and pressure vessels.

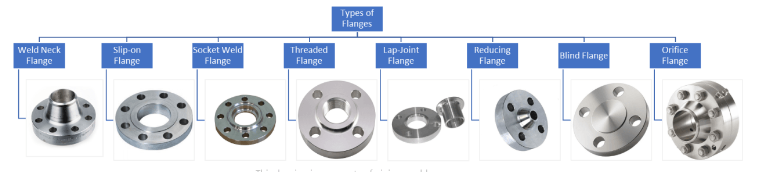

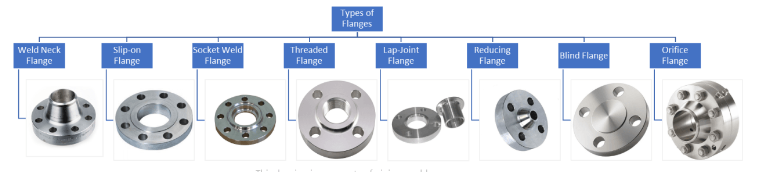

What are the main flanges?

In piping systems have many types of flanges and representative flanges are mainly: Slip-on Flanges, Welding Neck Flanges, Socket Weld Flanges, Lap-joint Flanges, Threaded Flanges, Blind Flanges.

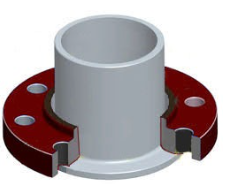

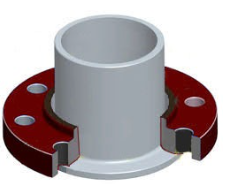

Slip-on Flanges

Slip-on Flanges

Slip-on flanges are installed on pipes by slipping on the flange hole onto the outside diameter of pipe and securing it to the pipe with fillet welds.

There is no full penetration weld between the pipe and slip-on flanges, so the joint cannot be radio-graphed.Slip-on flange are available with single fillet welds or double fillet welds.

Advantages and Disadvantage of slip-on flanges

Advantages

Lower purchase cost

Less skill required for installing due to the use of fillet welds instead of full penetration butt welds

Pipe ends do not require welding end preparation

Reduced precision in the pipe cutting length

Disadvantages

Flange installation requires the use of two fillet welds

The installation cost is about the same as welding neck flange because non-destructive testing is required for both welds

Slip-on flanges are unsuitable for some cyclic loads

The strength of a slip-on flange is less than that of a weld neck flange,etc

Welding Neck Flanges

Welding Neck Flanges

In the industry welding neck flanges are often referred to as weld neck flanges or WN flanges.

The Welding Neck Flange consists of a tapered hub which is secured to the pipe by full-through butt weld.

Due to the additional reinforcement area available of the hub of weld neck flange and the installation by welding, the hub becomes an integral part of the pipe.This gives a weld neck flange greater strength and integrity than slip-on flanges and ability to withstand higher bending moments.

Advantages of welding neck flanges

Butt welds allow radio-graphic non-destructive inspection to be carried out on the weld neck flange unlike slip-on flange which can only be inspected by magnetic particle inspection or dye penetration inspection

The weld neck flange can be directly welded to butt-weld fittings like elbows,tees or reducers without any short pipes

Although the initial procurement cost of weld neck flange is higher than a slip-on flange, the installation cost reduces the difference

Welding neck flanges can withstand higher bending moments and are suitable for piping systems subject to high pressures,high cyclical loads, high temperatures as well as cryogenic services

Socket Weld Flanges

Socket Weld Flanges

Socket weld flanges consist of a socket where the pipe is secured by a fillet weld at the outer hub. Since socket weld flanges are joined to the pipe by fillet welds, they are not considered as high-integrity joints. Radiography is not acceptable for joints that are fillet welds. Nondestructive inspection of socket weld flanges adopts magnetic particle inspection or liquid penetrable inspection.

Lap-joint Flanges

Lap-joint Flanges

A lap joint flange is a two component assembly consisting of a short end and a backing lap-joint ring flange.The short end face acts as a raised face of the flange since its outside diameter corresponds to the dimensions of the raised face portion of a flange.Only the stub end comes in contact with the process fluid.

For this reason, lap-joint flanges with short ends are used as a cheaper alternative to slip-on flanges in piping specifications for corrosion resistant materials such as stainless steel or titanium.In corrosion resistant material, the cost of corrosion resistant stub end with carbon steel backing lap-joint ring flange is lower than that of complete slip-on flange.

And the backing ring is loose fit on the stub end,this advantage reduces the installation effort during the fabrication process as no prior alignment is required.This function is also suitable for large diameter flanges, at locations where rotational adjustment is required and in services that require frequent dismantling for inspection and cleaning.

Threaded Flanges

Threaded Flanges

Threaded flanges can be used in piping systems where it is not possible to weld the flange to the pipe.The threaded flanges screw onto pipe with external tapered pipe threads.Most Engineering Organizations limit their use for a size range from 1/2" to 4" and for utility services.

Blind Flanges

Blind Flanges

Blind flanges are installed at the end of a piping system either on a main or branch connection or on valves as a means for positive isolation of the piping system. Piping headers can be terminated at the ends using a butt-weld cap. On drain systems blind flanges serve as important pole points or are removable for easy inspection. Blind flanges can be drilled and used as reduced slip-on flanges and the blind flange can also be drilled and tapped as a threaded reducing flanges.Blind flanges are available with the same pressure ratings as weld neck flanges and with a variety of gasket faces.

English

English